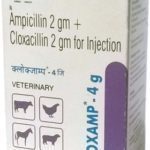

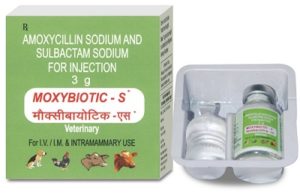

Therapeutic Group : ANTIBACTERIALS

Sector : VETERINARY

Mode of action:

Bactericidal in action, inhibits biosynthesis of the cell wall peptidoglycan which leads to cell wall lysis results in death of bacteria.

Spectrum of activity:

Gram + ve bacteria susceptible to penicillin

Reconstitution and Route of administration:

Reconstitute by Adding 15ml sterile water for injection and inject intramuscular immediately.

Withdrawal Period:

Milk: 7 days; Meat: 28 days

Indications:

Actinomycosis, Anthrax, Black leg, Tetanus, Arthritis, Mastitis, Metritis, H.S., Foot rot, Septic wound and GI tract and respiratory tract infections etc.

Contra Indications:

Benzathine Penicillin is not for use in turkeys producing eggs for human consumption or for use in horses intended for food

Dose:

Cow, Buffalo, Sheep, Goat, Pig and Horse: 12,000 IU / kg B.wt

Dog and Cat : 40,000 IU / Kg Body Weight or as directed by a registered veterinary practitioner.